How to Maintain and Adjust Reel Mower Cutting Units

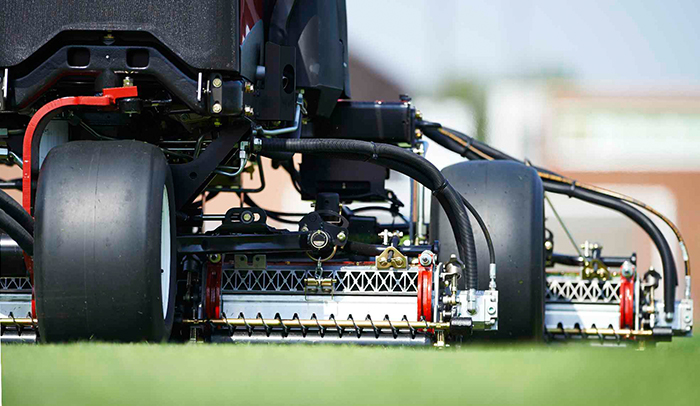

Quite often, sports fields and golf courses are judged by the appearance of their turf and greens — which is dependent on the cutting performance of your reel mower. To ensure a good quality cut and great after-cut appearance, it’s important to perform routine maintenance checks on your reel mower’s cutting units. To help you understand what proper cutting unit maintenance looks like and give you the tools to develop your own regular maintenance routine, we’ll discuss the three most common areas of concern.

1) Maintain Light Contact

Toro recommends maintaining light contact between the reel blades and the bedknife to promote a healthier turf and great after-cut appearance. When light contact is not maintained and there is no contact (a gap between bedknife and reel blades), the cutting edges will not cut the grass cleanly (will tear the grass leaf). If there’s too much contact, an increase in horsepower will be needed to spin the reel. In both cases, the reel and bedknife cutting edges will wear faster — which will increase the potential of dull cutting edges and need for additional maintenance — and negatively affect cutting performance and the after-cut appearance.

To check if your cutting unit is properly adjusted to light contact:

- Place the Toro® shim (part #140-5531) between the bedknife and reel blade.

- Adjust both ends of the bedknife until the reel blade pinches the shim against bedknife.

- Remove the shim and turn the Dual Point Adjustment 2 – 3 times (0.002 – 0.003″ tighter) to create light contact between bedknife and reel blades.

- Place the Toro cutting paper (part #125-5623) between the bedknife and reel blades. If you’re able to cut the paper evenly across the entire width of the bedknife, then you’re all set. If not, you’ll need to sharpen your cutting edges (bedknife and/or reel blades).

2) Keep Cutting Edges Sharp

Dull reel blades and bedknife cutting edges will not cut grass blades cleanly, which will damage turf and affect after-cut appearance. Some telltale signs that your bedknife and/or reel blades are dull include streaks in the grass, frayed or brown grass tips (i.e., tip dies back), increased grass stragglers, uneven height of cut or noisy cutting units due to knicks on the blades. To make sure it never gets to this point, it’s important to perform regular paper cut checks and inspect cutting edges for nicks and chips.

For paper cut checks, you can use Toro cutting paper (part #125-5623) to help assess cutting sharpness. Simply place the narrow strip of paper between the reel and bedknife and spin the blade to see how well it cuts. If you get a sharp, clean scissor-like cut, your blades are good to go. The key is understanding the amount of time the cutting edges become dull and performing sharpening maintenance before the edges are completely dull — which will prevent unacceptable cutting performance and after-cut appearance.

When it’s time to sharpen your cutting edges, there are different sharpening methods for the reel and bedknives. The bedknife has three main sharpening methods:

- Top and front grinding the bedknife (use Toro’s bedknife reference chart or operator manual for angle specifications).

- Rapid front facing the front angle (quick touch-up, make sure uniform, do not remove more than 10% of land width).

- Backlapping the cutting unit. And although you are backlapping the assembly, the resharpening is only affecting the bedknife due to the ratio of number of reel blades to one bedknife.

For all bedknife sharpening, a burr may develop on the cutting edge. Burrs should be removed using a sharpening tool or a piece of hard wood with care given to not break the sharpened edge. Lastly, you’ll want to make sure there is a small chamfer on the bedknife side where the reel blade comes onto the bedknife (e.g., lead-in chamfer) per operator manual instructions.

For the reel, there are two main methods for sharpening:

- Spin grinding, which sharpens the edge and restores the cylinder shape.

- Relief grinding to Toro’s 30-degree angle specification (narrows the reel blade width to reduce drag/HP and wear) when the reel blade land width is greater than 0.125 of an inch (3.2 mm).

After all sharpening, there will be a short period of time that the bedknife will hone (or mate) to the reel cylinder profile. The bedknife-to-reel contact should also be checked and readjusted (if needed) after a brief period of time (about 15 minutes of cutting time).

3) Adjust Height Cut Accordingly

The cutting units on your reel mower start with a “bench set” height of cut (HOC). This height is chosen based on factors in turf conditions, seasonal changes and playability requirements. Make sure the HOC is the same on each cutting unit. Even a 0.003 of an inch (0.08 mm) difference in height from end to end, or from one cutting unit to another, could result in a visibly mismatched turf.

For instructions on how to adjust your cutting units, refer to the operator manual for your specific mower model. If you want to learn more about how to maintain the cutting units on your reel mower, you can check out a variety of service tips and parts and service videos available on toro.com. We also recommend contacting your local Toro distributor for additional service details specific to your mower. For more updates, be sure to follow @ToroGrounds on Twitter.