Keep Your Topdressers in Top Shape

Toro helps you handle your topdressing needs quickly and precisely with the ProPass™ 200 Broadcast Topdresser and the MH-400 Material Handler. The equipment is designed for efficient operation and long-term performance, and this article will cover best practices that help ensure you continue to get a high level of performance from your equipment.

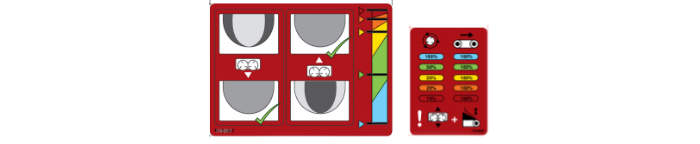

Use Your Decals

For maximum efficiency, you want to be sure the belt is operating at 100% and that the gate has the ideal opening for your application. Performance can be affected by the material being used and by its moisture content. For instance, you might need to reduce the gate opening slightly from the initial settings when handling dry sand, and you may need to increase it slightly for wet sand.

Moisture content can vary day to day, so it’s essential to follow the color-coded guidelines on your machine. The color codes on Toro topdressers are designed to help set up each portion of the machine for the most efficient operation. You want all of the operations to be set to the same color based on your application.

Make Spinner Adjustments

The spinner positions control the spread of material, so you want to be sure they’re correct so that you can get the desired topdressing effect. A fast spinner speed will widen the arc for broadcasting the material, and a slower speed will reduce the arc. Once the initial settings are made, you can make any minor adjustments needed to account for the moisture content of your materials, width of spread and more. Once again, you can use your color-coded decals to make the adjustments.

To avoid dropping too much material in the center of the spread pattern, slide the base “IN” toward the hopper. If too much material is being cast to the outer edge of the spread pattern, move the slide “OUT” or away from the hopper.

Replace Worn Decals

On some equipment, decals provide helpful information. On topdressers, they provide essential information that can help you maximize efficiency and get the results you desire. Over time, debris and weather can cause decals to fade or become too worn to read. Because they’re such an important part of the operation of topdressers and material handlers, Toro makes replacement decals readily available:

Replacement Decals for the ProPass 200 Broadcast Topdresser

- 119-6814 Operation

- 119-6819 Wireless control only

- 119-6820 Spinner speed

- 119-6808 Tailgate volume

- 119-6816 Slide adjust

- 119-6817 Fine tuning

Replacement Decals for the MH-400 Material Handler

- 119-6823 (SH models only)

- 119-6819 (Wireless control only)

- 119-6869 Tailgate volume

- 119-6832 (EH2 models only)

You can order the decals directly from the Toro parts catalog or through your local Toro distributor.

More How-To Help

The how-to series is designed to help you get the most from your Toro equipment. If you missed any of the previous articles, just click on the titles below. You can also check out our Video Hub for more how-to instructions and advice.

Reduce Costs with Hybrid Technology

Extending the Life of Your Sprayer

Maintaining the Ideal Quality of Cut

Extending Equipment Life with a Fuel Stabilizer

How to Choose a Rotary Blade or Bedknife

Tier 4 Regeneration

Hose Maintenance

Use Service Reminders to Ensure Timely Maintenance